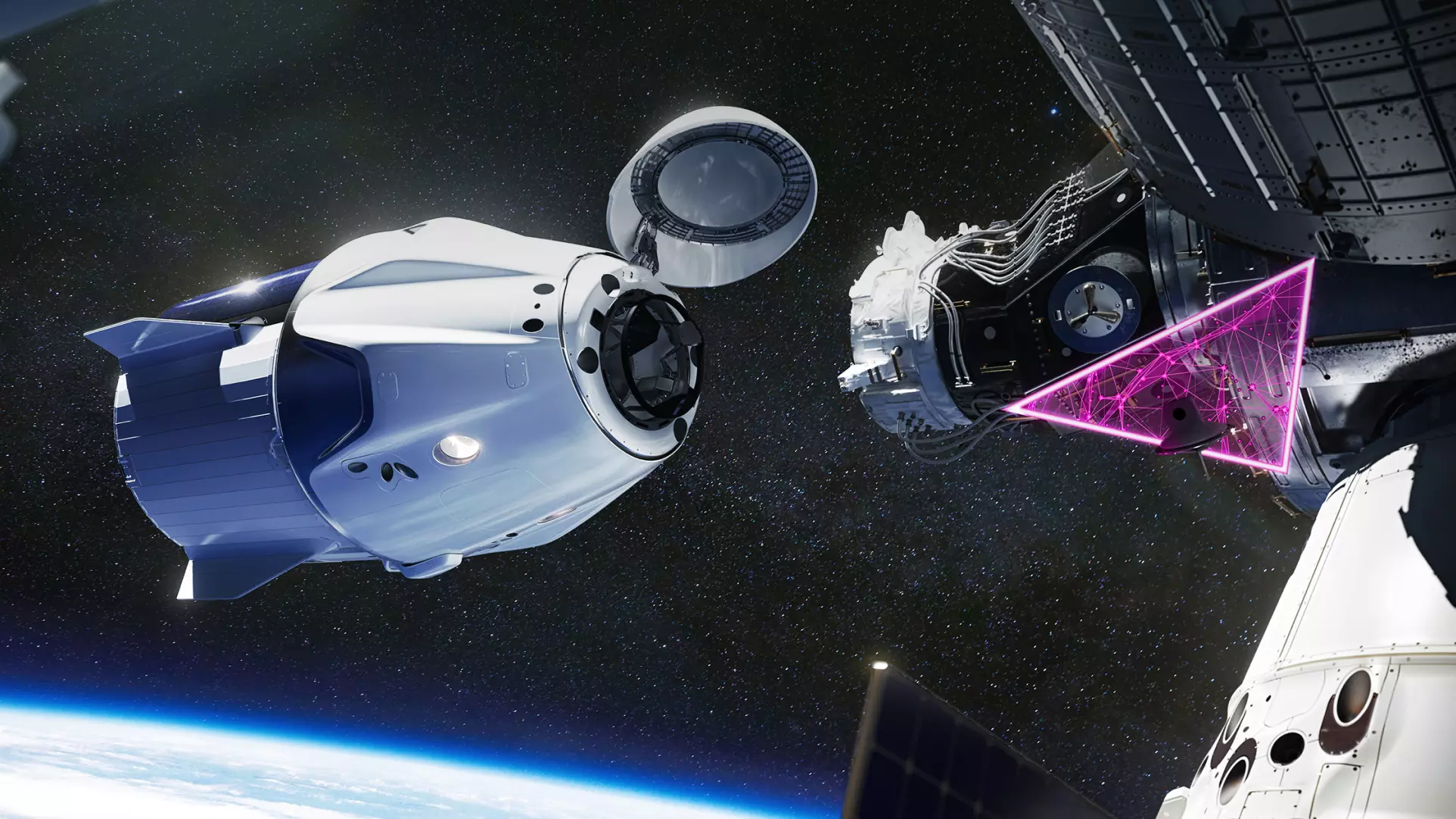

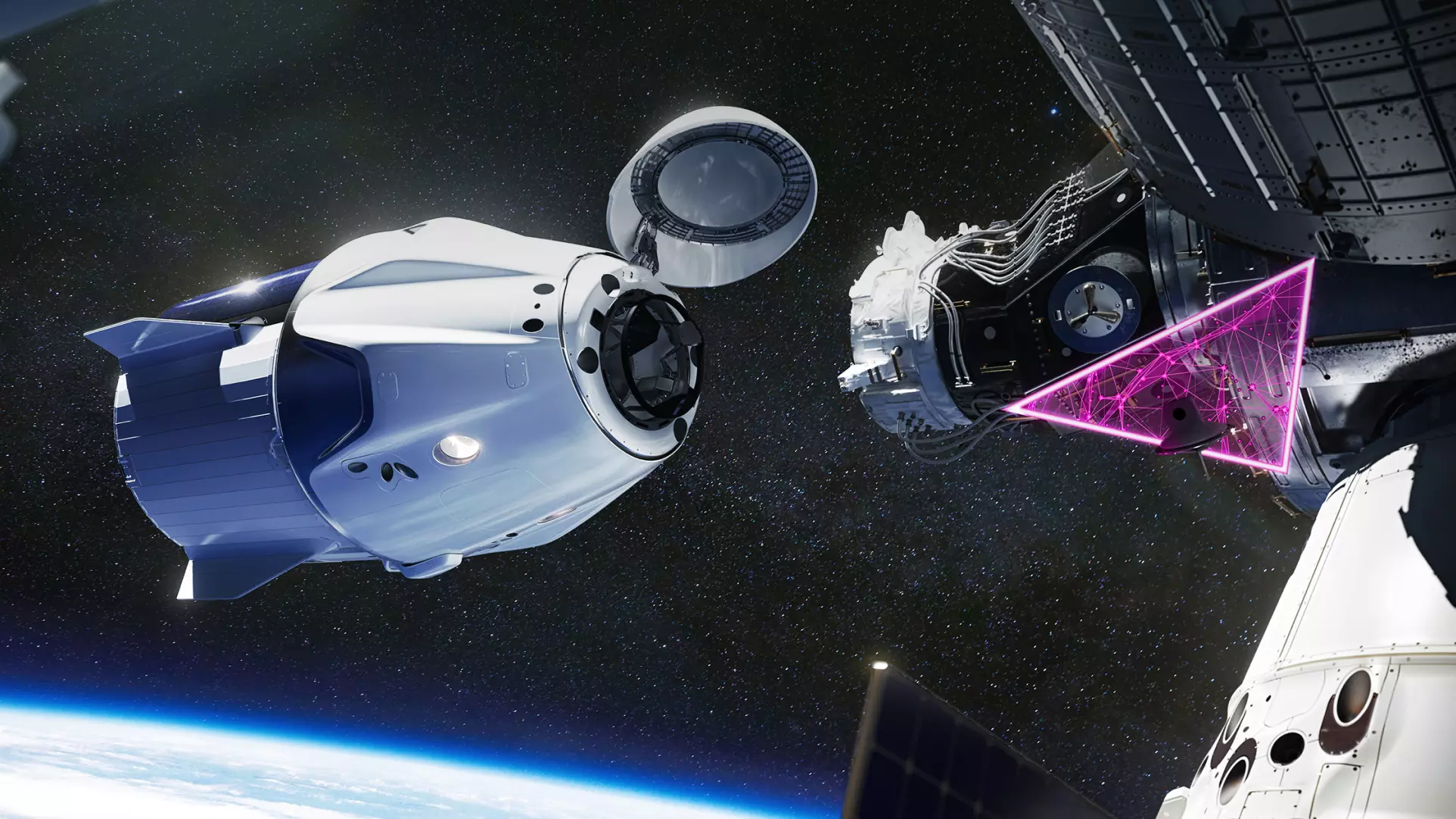

Next-gen ROI

Our technology is being used on this planet and beyond by some of the world’s largest and most respected companies. Check out our case studies along with insight from across the industry.

Filter

Sorry, no posts matched your criteria.