Abyss Lantern Eye™

Mooring chain inspections are costly, tedious, operationally challenging, and often result in inconclusive findings with current inspection methods. Divers or ROVs equipped with callipers can take high precision measurements. The error tolerance on these measurements is submm when reviewing the integrity of a mooring chain link, however, the inspection technologies are error-prone and struggle to reliably achieve accuracy. Furthermore, the inspection is time-consuming, increasing ship time, which can cost hundreds of thousands of dollars per day.

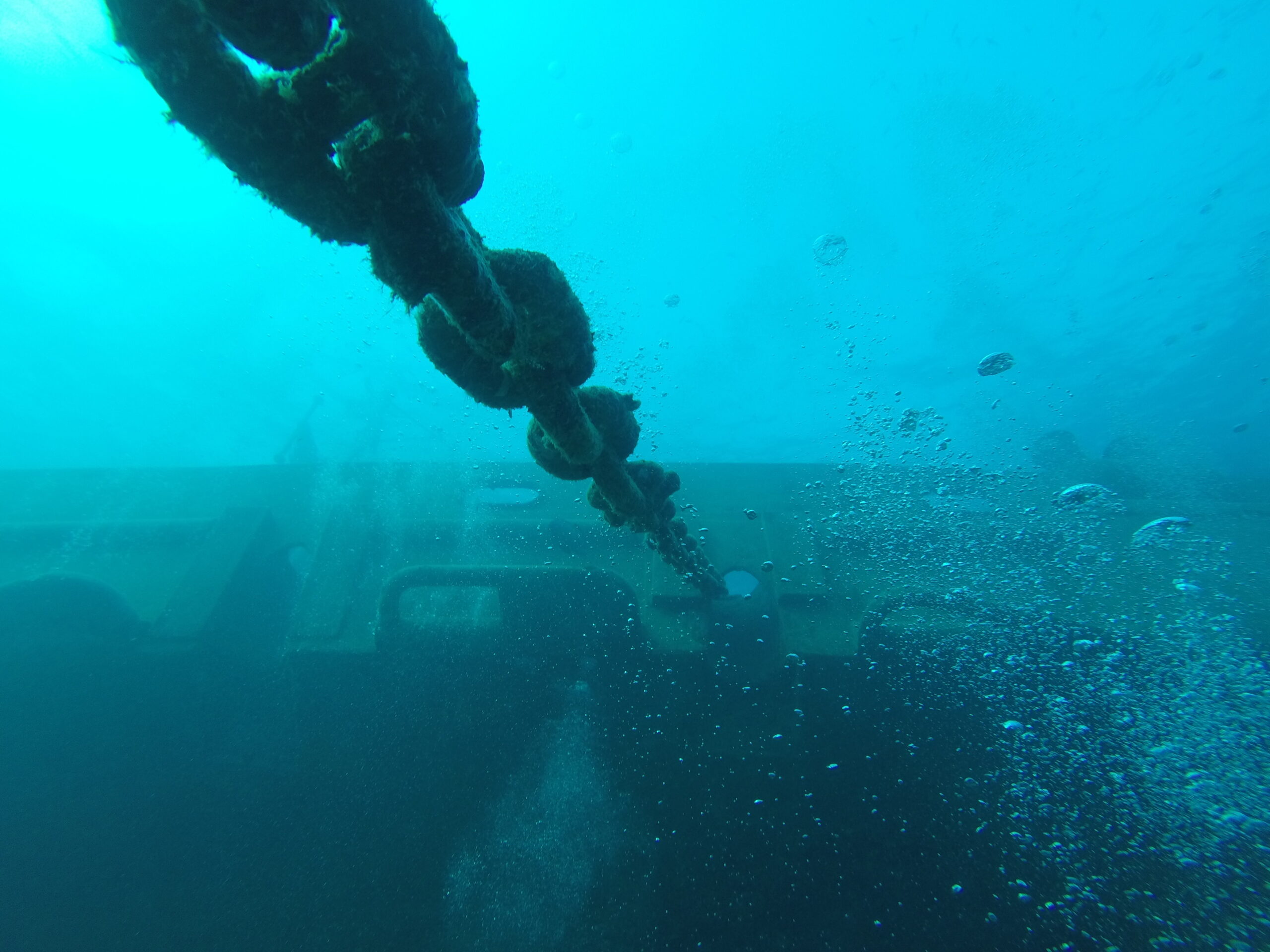

A large player in the oil and gas sector engaged with Abyss to test our patented camera system, Lantern Eye™ S, to provide high precision, low-cost mooring chain inspection. We quickly sent an Abyss imaging specialist to the asset in the Gulf of Mexico. There, he worked alongside an ROV team to integrate the Lantern Eye™ S onto an ROV and conduct a mooring chain inspection.

The high-precision inspection camera, with the smallest form factor in its class, was easily integrated within a matter of hours (other technologies can take days). The ROV hovered near a chain link while the Lantern Eye™ snapped away, and the subsea inspection for the links was conducted in minutes rather than hours.

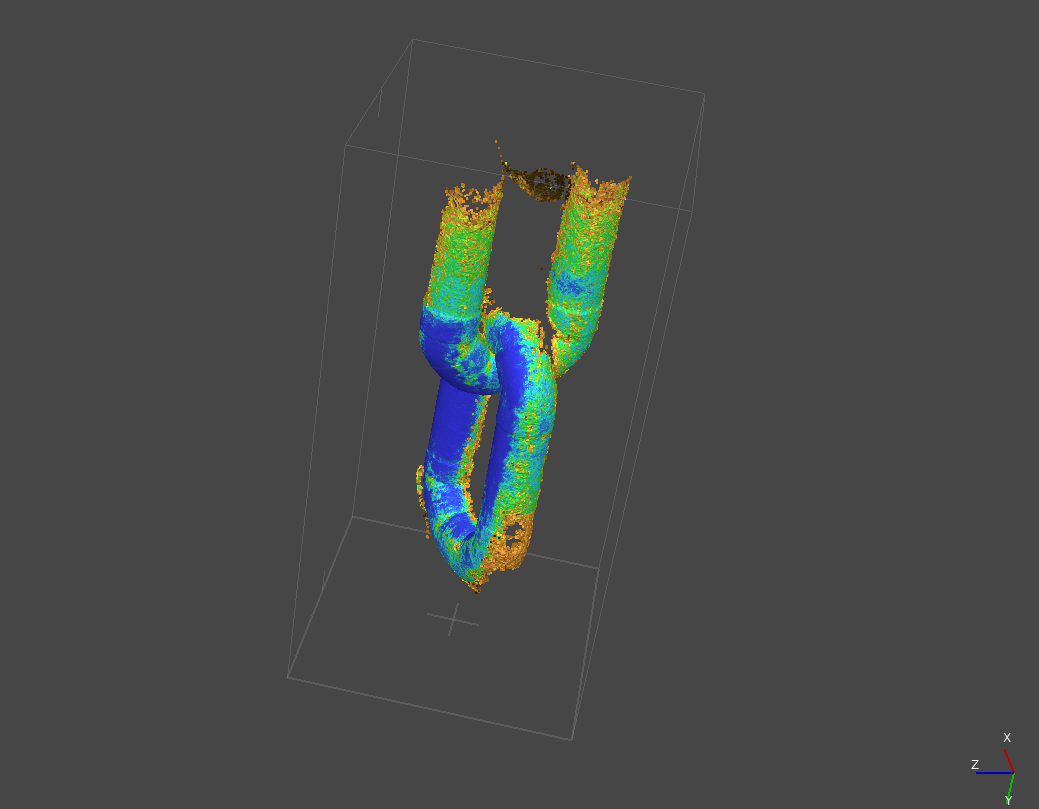

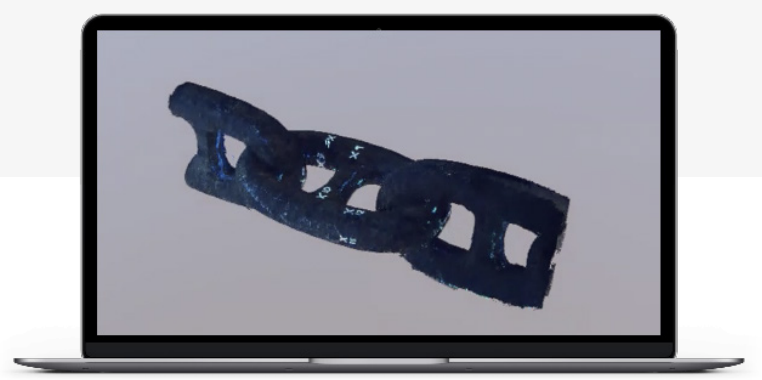

A rich digital twin and 3D reconstruction of the links were produced in an instant. Overnight the data was further processed to return sub-mm precision.

Following the pilot, the technology demonstrated repeated success in highly accurate metrology for various clients. It is now in the final stages of getting class certification and approvals.