Next-gen ROI

Our technology is being used on this planet and beyond by some of the world’s largest and most respected companies. Check out our case studies along with insight from across the industry.

Filter

Asset Integrity in the Energy Sector: Unprecedented Challenges and Solutions

In the energy industry, asset integrity is what keeps everything running safely and reliably. Whether it’s a pipeline in the refinery, a pressure vessel on an FPSO, or a subsea structure on the ocean floor, maintaining the health of these assets isn’t optional—it’s critical.

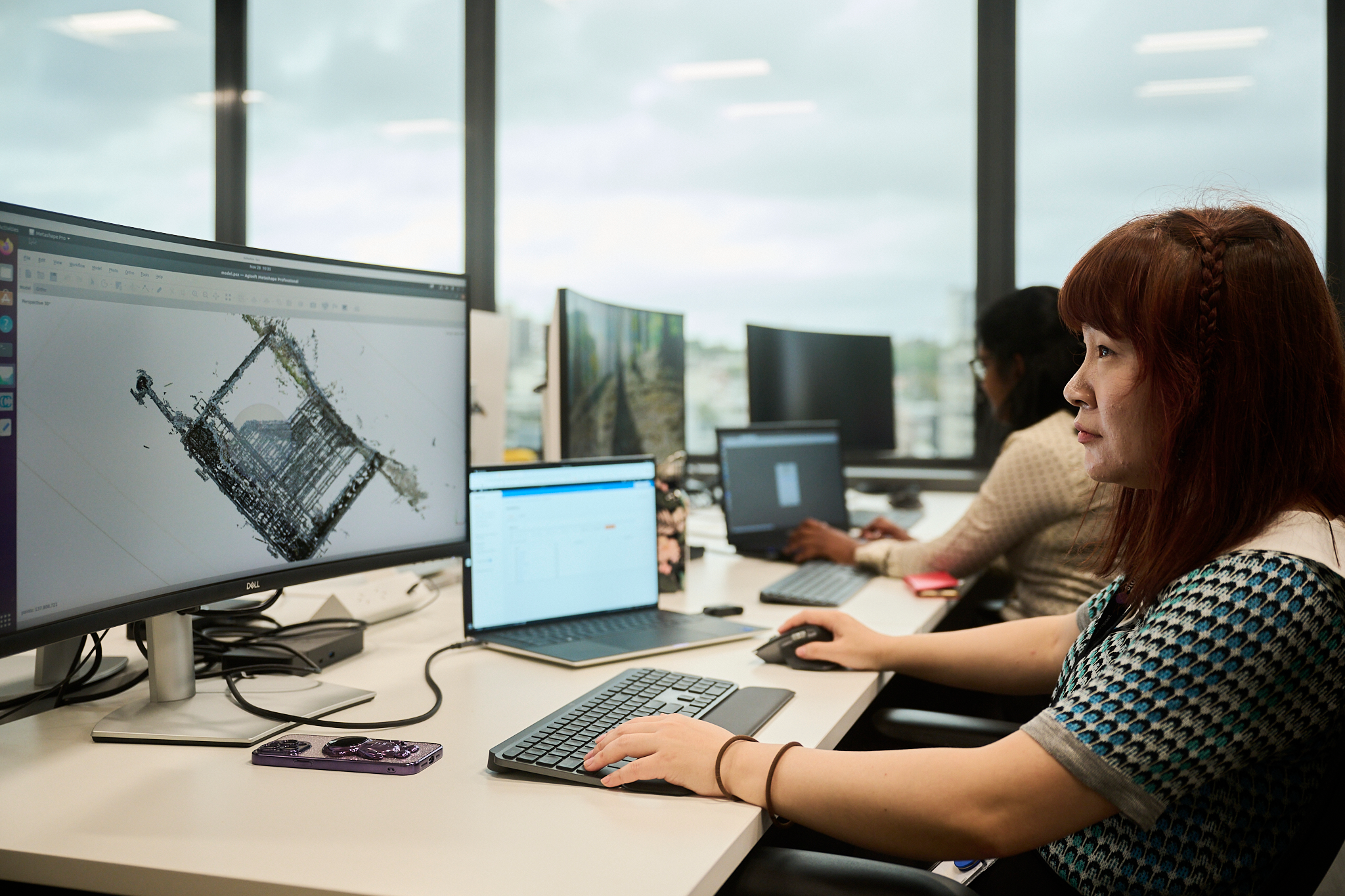

Applus+ in Australia partners with Abyss Solutions

Applus+ in Australia partners with Abyss Solutions to revolutionize Non-Destructive Testing with Artificial Intelligence

Thames Tideway Tunnel Project

Abyss was able to identify all defects down to 2cm, with a location accuracy determined to be no greater than 5cm.

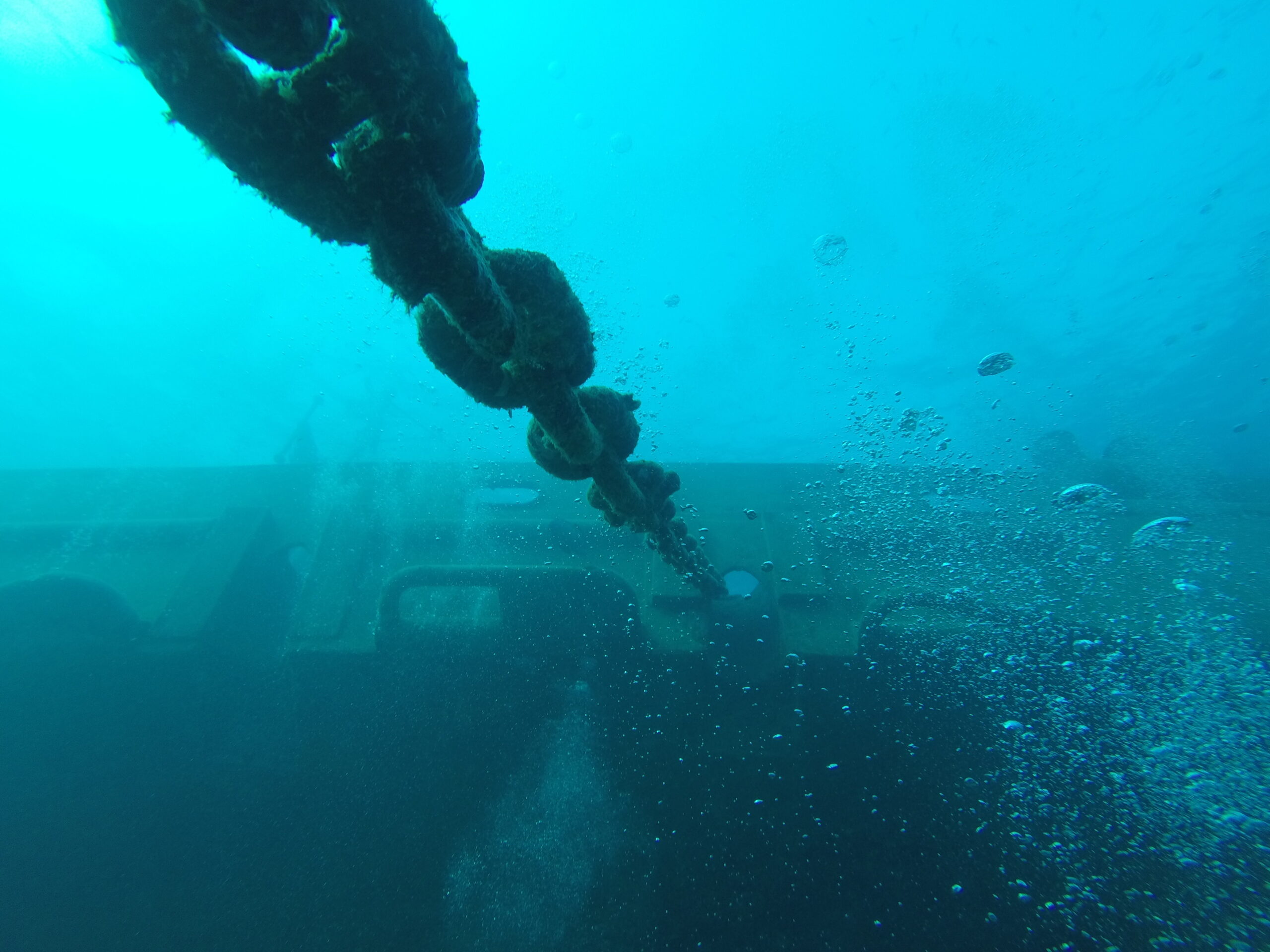

Transforming Subsea Inspections with Remote-Operated Lantern Eye™ System

Abyss Solutions’ pioneering Lantern Eye™ system, now operable remotely, represents a significant advancement in subsea inspections.

How Abyss Improved Splash Zone Inspections with Lantern Eye™ Air (LEA)

By utilizing optical stereo photogrammetric imaging, LEA transcends the limitations of traditional caliper-based methods, providing unprecedented accuracy and repeatability in measurements derived from 3D models.

Bat Monitoring Case Study

The client was searching for a way to understand where the bat colonies were located within the tunnel since the interior consisted of both rough-cut rock and concrete.

Atmospheric Corrosion Detection & Management with Artificial Intelligence

Abyss’ AI-based system successfully detected corrosion and coating degradation across an offshore platform and prioritized remediation.

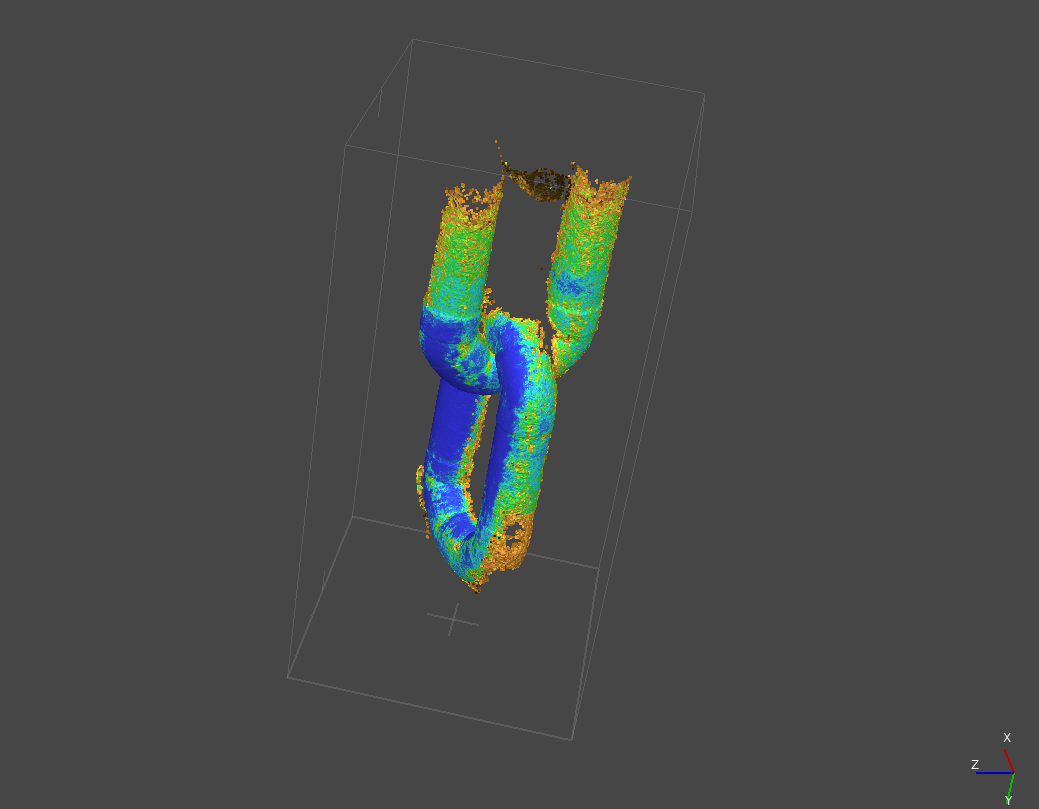

Revolutionizing Subsea Inspection with ABS-Class Certified Lantern Eye™ S

Abyss Solutions’ Lantern Eye™ S represents a paradigm shift in subsea mooring chain inspection. This case study highlights its deployment in the Gulf of Mexico, demonstrating compliance with stringent class standards and offering superior value to customers in the oil and gas sector.

Stereo Image System for Inspection of Mooring Chain in the Splash Zone

This article outlines an optical stereo photogrammetric imaging system, called the Lantern Eye™ Air (LEA), for inspecting the mooring chain above the water in the area known as the splash zone.

Tried and tested in the field

Speak to a member of the team about how we are delivering next-generation solutions for some of the world’s most respected global businesses.