Growing with Abyss Solutions

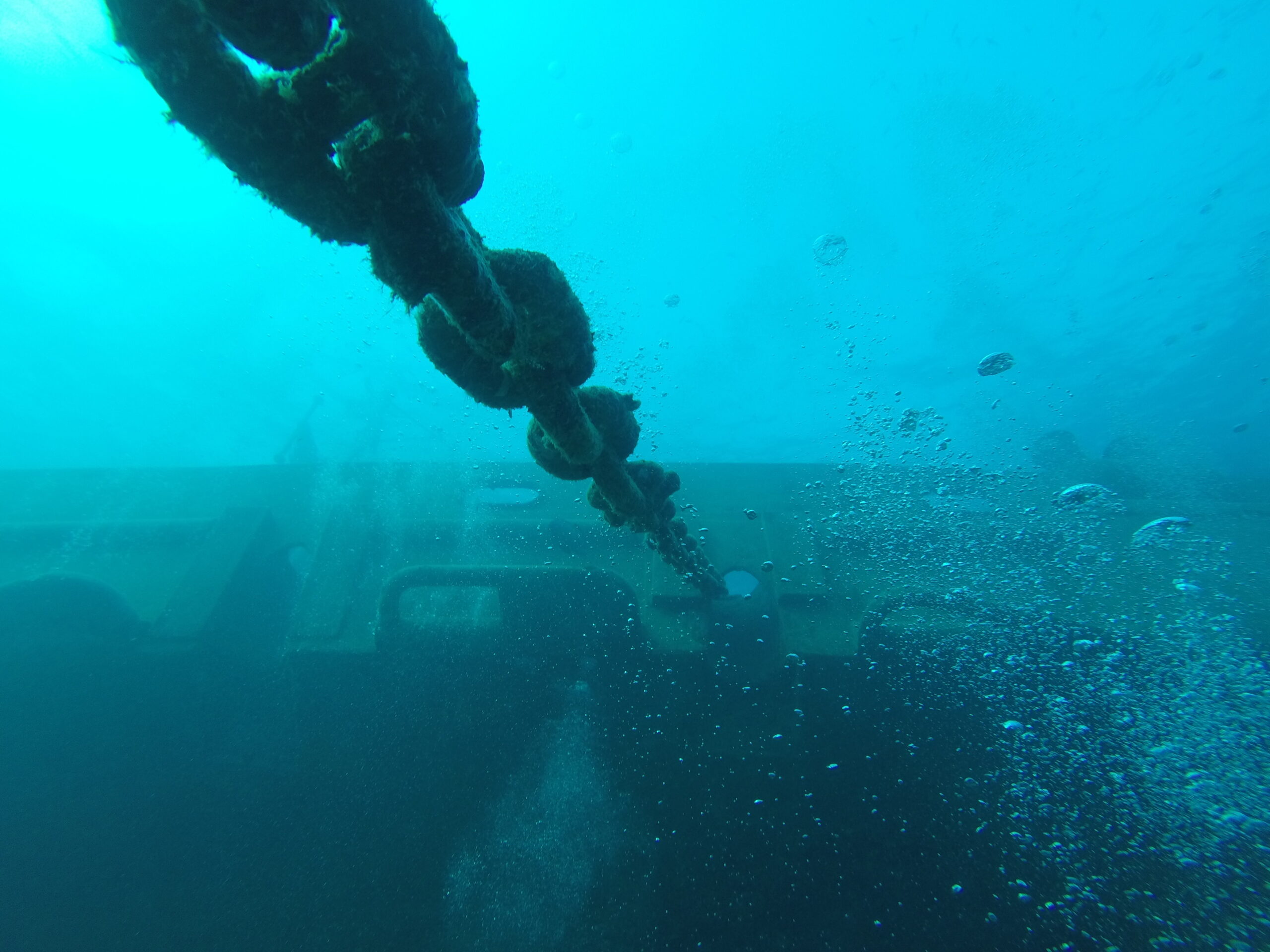

Three years into my bachelor’s degree in mechatronic engineering, while looking for internships, I was fortunate enough to be given the email address of someone at Abyss Solutions. Equally fortunately, Abyss decided to take a chance on me for a summer internship within the robotics team. I couldn’t believe my luck, a real robotics company! I have been working with Abyss ever since.

It’s now been a little over three years since I started that internship, and a lot has changed:

- The company has more than quadrupled in size.

- Our products have matured significantly.

- My job description has changed (more than once).

When I started at Abyss Solutions, my software skills were… underdeveloped. I have always loved hardware. During my internship alone, I was able to pick up a huge amount of software knowledge from working with experienced software engineers. The more I worked with software, the more I enjoyed it.

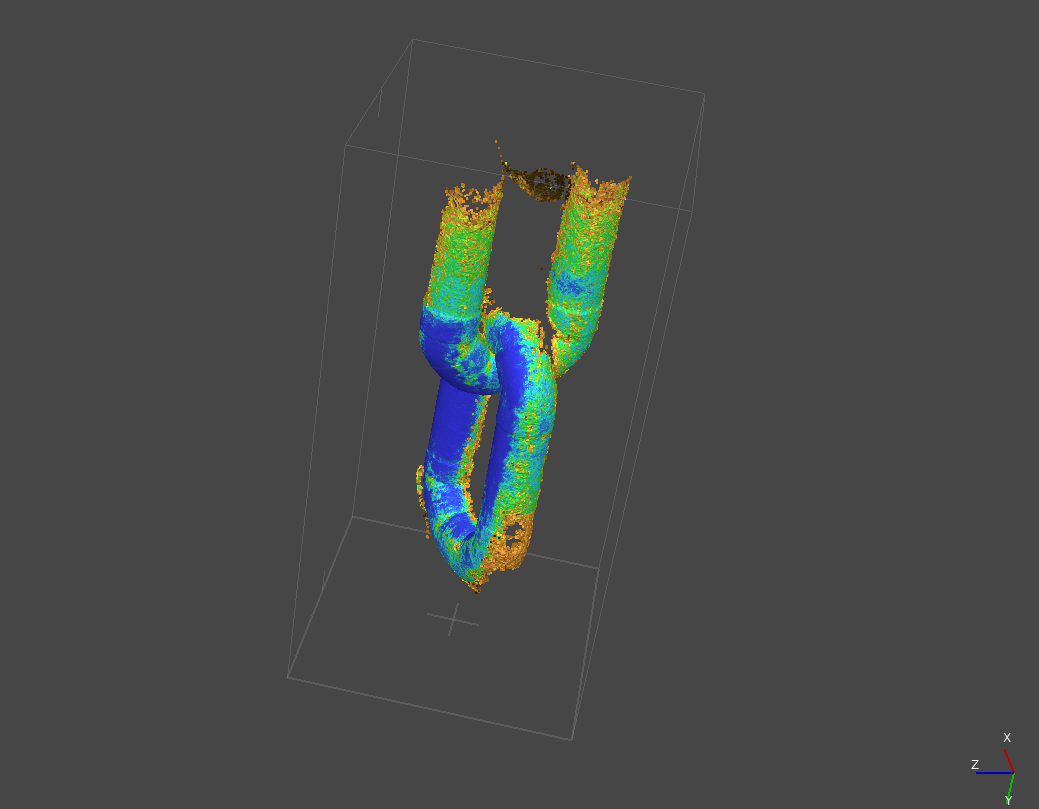

Before long I was working as a software engineer for the robotics team, primarily on offline post-processing work (as opposed to real-time software running on the robotic platforms). I loved this work and learned a lot from it.

Recently I was given the opportunity to move into the machine learning team, where I am putting my software skills to work while also learning the ways of ML from the experts.

Working at Abyss has always been a pleasure, and I feel so privileged to have been able to work with, and sponge knowledge from, such extraordinarily talented people. I am excited for the future, not just in terms of my personal growth, but also for the growth of the team as we scale up our operations and tackle new problems. It truly feels like we’re all learning together (probably because we are), and that fosters an egalitarian work culture, which is undoubtedly one of my favourite things about Abyss.