Underwater Visual Inspection, Measurement, and Fault Identification via Remote Teleoperation

Abstract

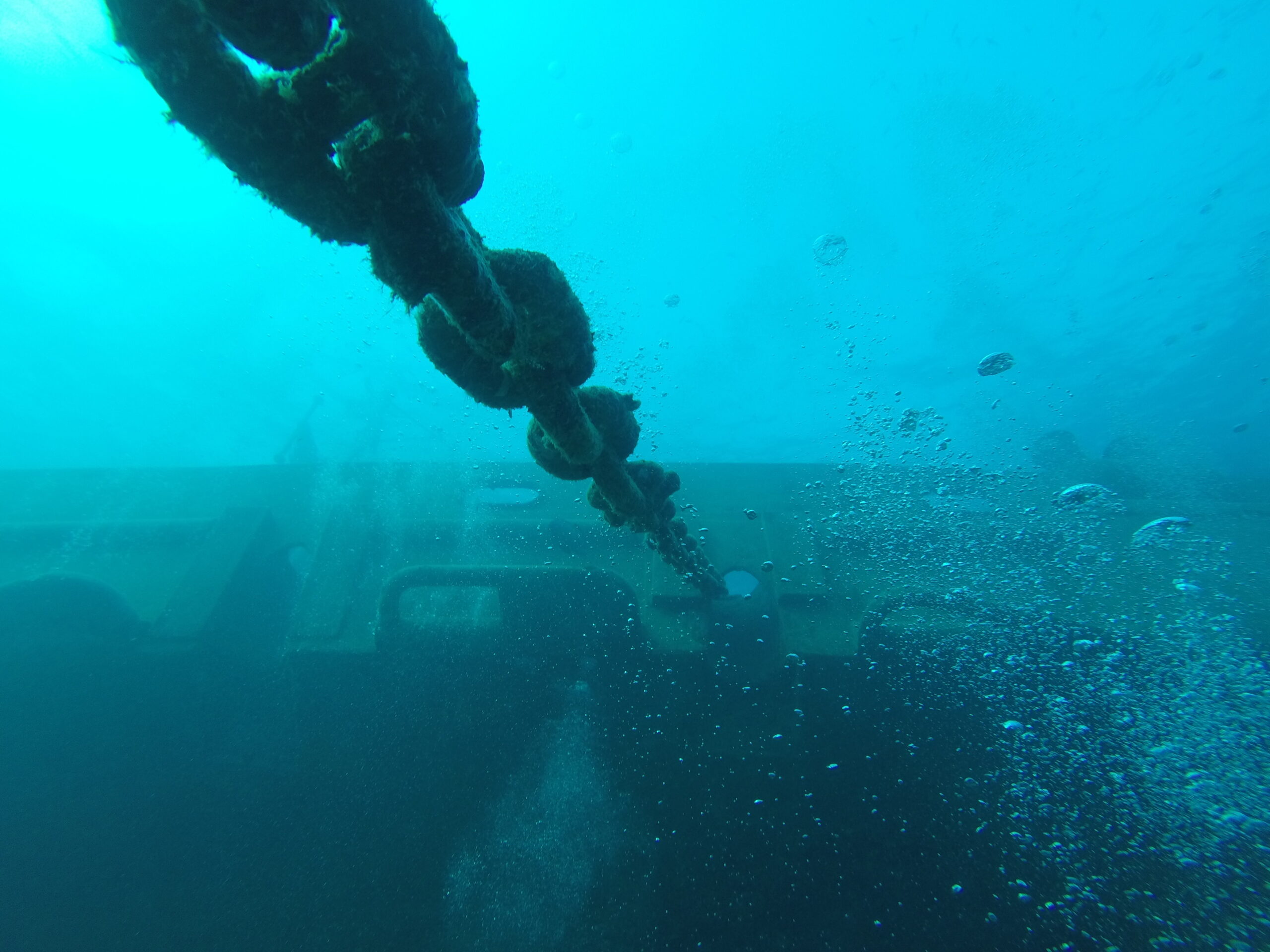

Inspection of underwater assets on oil and gas offshore platforms is required to assess asset integrity, and aid lifetime extension analysis. These assets include mooring chains, fairleads, anodes, and ballast tanks. Typically, a range of tools including calipers, cameras, and inclinometers are used to take measurements and do Close Visual Inspection (CVI) of these objects. Limitations of these inspection techniques include inaccuracy in results, having dedicated personnel onboard (POB) the vessel, significant vessel time being used, and potential damage to the inspection ROV in unfavorable sea states. This post discusses the Lantern Eye™ S (LES), a compact contactless visual metrology system developed by the authors to solve these problems.

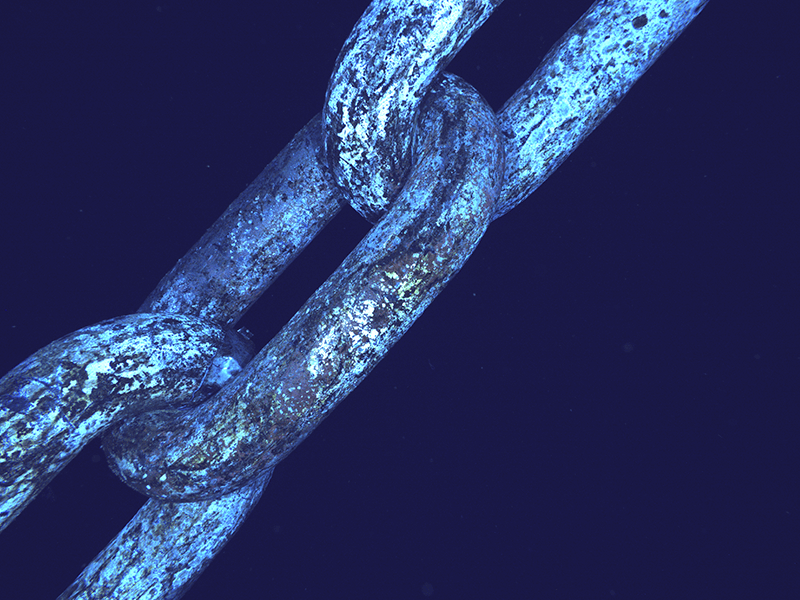

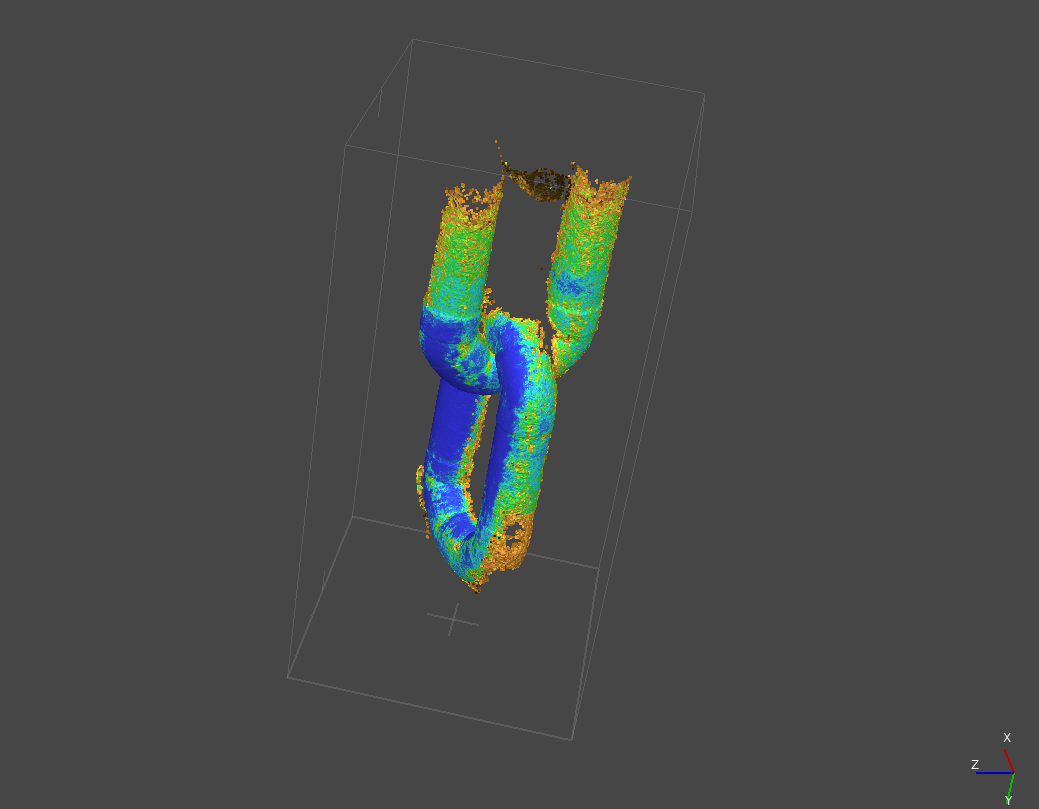

The patented Abyss Lantern Eye™ S is a stereo imaging system, which includes a stereo camera pair linked to a set of underwater strobe lights. It can be deployed on mini-ROVs (down to the 30kg class) or working-class ROVs (multiple tons). Inspection data can be live streamed over an internet connection to a remote operator, this facilitates real-time remote operations and a reduction in POB. Post-processing of the high-fidelity imagery creates scaled sub-mm accurate 3D models for distance and inclinometer measurement analysis. Faults commonly found on subsea assets can be detected and classified, including, general corrosion, paint degradation, pitting, deformation, and fracture. To ensure the accuracy of the system, in-situ calibration is conducted to account for the water environment – primarily to account for salinity in the water. Initial results are available in 5 minutes allowing on-the-spot decisions and assessment, and final results are available in 8 hours for detailed inspection. Measurements can be automatically extracted, and comparisons are made to as-built drawings. The contactless and multipurpose functionality of the LES can reduce vessel time and inspection costs as it eliminates precarious (dependant on sea state) ROV manipulator arm holding operations, reduces tooling change downtime, and can replace traditional CVI. Furthermore, the high-quality engineering insights enable asset owners to plan data-driven asset integrity and lifetime extension maintenance regimes which can aid in the reduction of insurance premiums. Two separate case studies present these findings, showcasing that remote offshore integration and deployment is indeed possible thereby reducing POB, and that vessel time and risk to ROV operations can be reduced by using a contactless multipurpose metrology tool.

Authors

Jordan Jolly; Lashika Medagoda; Thomas Van Bruggen; Mitchell Galea; Jeff Mohammed; Suchet Bargoti; Abraham Kazzaz; Masood Naqshbandi; Nasir Ahsan